Industrial Things in a Post-Industrial Society

The Life and Afterlife of a Chinese Glass-Forming Machine

In the former industrial suburb of Baoshan in Shanghai, in a corner of the Shanghai Museum of Glass (上海玻璃博物馆; ShMoG), rests a decommissioned Owens-Illinois double-gob individual section (IS) glass-forming machine. Surrounded by gleaming glass treasures, the cold steel object is a remarkable sight, but what is it doing there, and what does it mean? This essay explains how, in the space of the museum, the industrial thing is at once a real link to the past, an abandoned thing relieved of the duty to mean anything at all, and a surreal stranger in its own land. Both present and absent, it destabilises traditional notions of progress, modernity, and socialist utopianism, and in so doing invites the possibility of transition to post-industrial and post-socialist society.

Arjun Appadurai has made a notable contribution to the way we talk about the complex and conflicted identity of things by suggesting that we treat them not as stable entities but as processes. First, he asks us to consider that the thing is a commodity; second, that commodities are exchanged; third, that it is the exchange of the commodity that creates value. Through exchange, the thing becomes invested with social relations. If we are to understand these social relations, we are obliged to follow the ‘trajectory of the thing’ as it moves through different phases of existence (Appadurai 1986). Igor Kopytoff adds that by tracing the diversion of that thing from commodity to abandonment and onward to singularisation as art/heritage, we may begin to appreciate not only the thing itself, but also the moral economy in which it is exchanged. In his words:

In the homogenized world of commodities a colorful biography of a thing becomes the story of the various singularizations of it, of classification and reclassifications in an uncertain world of categories whose importance shifts with every minor change in context. As with persons, the drama here lies in the uncertainties of valuation and of identity. (Kopytoff 1986: 90)

Appadurai’s approach may be usefully applied to glass-forming machines. In their first phase of existence, such machines appear as dynamic instruments of global capitalism and socialist production, having trajectories that powerfully illuminate their social contexts, whether it be the American Midwest, wartime Shanghai, or Mao-era Qingdao. The trajectory thesis, however, is never really about the thing itself and so cannot cope with the possibility of there being no moral economy in which the thing is exchanged. The second, brief section of this essay considers that eventuality by observing the abandonment of a 1990s-era glass-forming machine and the 1950s-era glass factory in which it now rests. The removal of the machine and the factory from the supply chain at the end of the twentieth and beginning of the twenty-first centuries abruptly severed the relationships that had kept them in motion and dissolved the networks that once defined their purpose. Stripped of their materiality, these industrial things may be remembered in terms of their past but can only be encountered sensually as an arrangement of materials. That reduction to material is critical to evaluating the machine’s current phase of existence, in which it appears not as a point in a trajectory, but as a semi-autonomous object existing in the asynchronous time and ambivalent space of the museum.

Phase 1: Glass-Forming Machines and their Dissemination in China

In the mid-nineteenth century, when glass producers were just beginning to experiment with mechanisation, jar and bottle production had changed very little from the time when it was first practised in ancient Syria. Quartz sand and additives such as soda ash were heated in a kiln to make raw molten glass; one worker inserted a gob of glass into a form held by a second worker and blew it into shape through a long tube. Efficient though it already was, the container industry was transformed at the end of the nineteenth century by the invention of semiautomatic glass-forming machines in Europe and America and, most notably, by the patenting of the first fully automatic machine by Mike Owens in 1903 (Meigh 1960) (see Figure 1). Glassworker guilds, restrictive licensing policies, and the massive scale of the Owens machine slowed its adoption, although by the end of the next decade, approximately half of American, and an increasing share of European and Japanese, bottle and jar production was being done with Owens machines (Journal of the Ceramic Association, Japan 1928). Karl Peiler’s invention of a flow-and-feed device in 1917 allowed glass producers to convert semiautomatic machines to virtually automatic, at once undercutting Owens’ command over the industry and advancing the pace of mechanisation overall. The final major innovation in glass-forming machines came in 1925 with the invention of the IS glassblowing machine by Henry Ingle at the Hartford Empire Company (Emhart Glass). This machine could send gobs of molten glass to multiple forming sections, blow them into an intermediate mould, transfer and blow them into a finishing mould, and deliver the completed bottle or jar to a conveyer belt—all within about 11 seconds (Miller and Sullivan 1984). After some 2,000 years of productivity, the age of manual glassblowing was all but over.

Chinese manufacturers were late in the race to mass-produce glass containers. Glass is not unknown in early Chinese history but there is little evidence of glassblowing being practised before 1680, when the Emperor Kangxi (r. 1661–1722) established a workshop for decorative glassware within the walls of the Forbidden City in Beijing. That workshop closed during the reign of Qianlong (1735–96), although by the mid-nineteenth century, a bustling glass industry had emerged in Boshan, Shandong. Boshan’s artisans produced a variety of objects and utensils, including glass ingots, panes, and blown-glass vessels, although like Kangxi’s imperial glassworks, Boshan was better known for high-end ‘Peking glass’ rather than the mass production of bottles and jars (Warren 1977).

Industrial glass technology first appeared in China in 1904 when the newly incorporated Boshan Glass Company gained access to German technology, expertise, and contracts with German enterprises (Yishibao 1923). Domestic and foreign-owned glassworks increased in number during the 1910s and 1920s and likely used some forms of mechanised production such as air-compression, although it was not until 1936 that Jinghua Glass Factory (晶华玻璃厂) in Shanghai acquired China’s first glass-forming machine—an American-made Lynch-10 semiautomatic fitted with a Hartford feed-and-flow mechanism supplied by a Japanese kiln. When the Empire of Japan invaded Shanghai the following year, Jinghua moved the Lynch-10 system to the relative safety of the foreign concession area. Despite the wartime conditions, the company expanded its production line with the acquisition of a second glass-forming machine. A third machine, which was stranded on a wharf in Manila for the duration of the Pacific War, arrived several years later. In 1950, the company transitioned to the communist era by merging with China’s oldest brewery to form the Qingdao-Jinghua Glass Company (青岛晶华玻璃厂), and one of Jinghua’s original Lynch-10s was shipped to Shandong, where it went to work making bottles for export-oriented Tsingtao Beer (Zhao n.d.).

In the 1950s and 1960s, glass bottles and jars became increasingly important to the Chinese economy, although Mao-era isolationist policies meant there were few opportunities for Chinese manufacturers to import new glass-forming machines. To meet the demand for glassware, engineers began to replicate the few operational machines they could locate in China. In 1956, Qingdao-Jinghua’s Lynch-10 was pulled off the production line and replicated by the Shanghai Mechanical and Electrical Design Institute. The resulting clones—eventually about 50 in number—were a breakthrough for Chinese manufacturing and many continued to operate into the 1980s. However, from a technical standpoint, the clones were already obsolete when they debuted in 1958. In the 1960s, other engineering teams continued the search for more efficient designs. Shandong Light Industry Machine Factory (山东省轻工机械厂), for example, was able to replicate and remanufacture a relatively advanced Emhart IS employed at the Guangdong Glass Factory (广东玻璃厂). The Shandong team repeated their success in the late 1970s and early 1980s by replicating a Belgian made ROIRANT S10 owned by the Qingdao-Jinghua Glass Company, and outfitting Weifang No. 1 Light Industry Machine Factory (潍坊第一轻工机械厂) to manufacture its copies (Shandong Province Qing Net n.d.).

The ‘reform and openness’ of the 1980s gave China’s engineers the opportunity to work more directly with foreign manufacturers. When Shandong Light Industry Factory turned its attention to another American-made glass-forming machine, at Beijing No. 2 Glass Factory (北京玻璃二厂), they realised there was more at stake than just a set of blueprints. Instead of simply copying the specifications as they had done in Guangdong and Qingdao, the unit signed a contractual ‘Technical Transfer of Complete Equipment for the Manufacture of Glass Bottles’ and then joined the American manufacturer to create Beijing-Wheaton Glass Company Limited in 1988. The Australian branch of the Owens-Illinois Glass Company followed in 1990, opening a group of six joint ventures in China including ACI Shanghai Glass Limited (澳联玻璃有限公司) in the Shanghai suburb of Minhang. There, as in any good biography, the Chinese glassblowing industry comes full circle, rejoining the global flow of commodity production that had delivered the first glass-forming machine to Shanghai in 1936. Eighty-seven years after Mike Owens invented his first automatic machine, ACI returned to the source and installed an Owens-Illinois glass-forming machine in its Shanghai plant. The machine would spend its life there making bottles for domestic and international brewers and distillers, including Anheuser-Busch, Suntory, and Jin Feng Rice Wine (AustCham Shanghai n.d.).

Phase 2: Abandonment and the Antisocial Life of Ruin

The end of the machine’s productive life and transition to post-industrial existence involve the abandonment of two worksites: the Shanghai No. 1 Glass Instruments Factory in the suburb of Baoshan, and ACI Shanghai Glass in the suburb of Minhang.

The Shanghai No. 1 Glass Instruments Factory (上海玻璃仪器一厂) commenced operation during the Great Leap Forward in 1958. Over the next three decades, the factory generated a steady stream of high-grade labware but, like countless other Mao-era socialist enterprises, finally went bankrupt and closed its doors in the 1990s. The place sat disused until 2008 when Zhang Lin, an executive with the Shanghai Glass Company, secured a lease on the property, intending to develop it as a museum. However, for years, much of the site remained in a shambles. In the early days, a few workers lingered in the factory’s old dormitories, but soon all that remained was trash: dusty old sofas, empty cabinets, random documents strewn about, and of course, glass—lots of glass. The junk was eventually removed, but the buildings still seemed oppressively empty. In the absence of machinery and garbage, the spaces were dominated by steel-reinforced concrete columns—the bane of any gallery developer—that were still needed to hold up the remains of the old workshops and warehouses. The museum reclaimed more of the old glassworks in 2015, although many buildings from the 1950s and 1960s were still observed ‘scattered among the weeds and rubble, with half-opened windows and open doors’ (Shen 2015). Heavy truck traffic along Changjiang Road continued to coat the museum in dust and the gigantic Shanghai Steel Mill clung to life a short distance to the east. It was apparent, nonetheless, that Baoshan was an ‘old industrial area in its twilight’ and out of step with Shanghai’s futuristic development model (Shen 2015).

The changes sweeping through Baoshan in the second decade of the century were also felt in Minhang. The economics that had once driven Owens-Illinois to move production away from Corning and Toledo now turned on Shanghai, as the company’s Asian branch began to move production to second-tier Chinese cities such as Zhaoqing, Guangdong Province, and other more cost-effective locations including Jakarta and Ho Chi Minh City. In 2014, the Minhang joint venture powered down its production line, stripped the plant, and sent its workers home. The Owens-Illinois IS glass-forming machine that had been the beating heart of the factory might have lived another life somewhere else, but it likely would have cost more to move, refurbish, and upgrade the machine than it was worth. In the productive environment of the factory, operating 24 hours a day, seven days a week, the heavy metal object had earned the illusion of permanence and a stable working relationship with its operators. Then, after 25 years of almost constant motion, it blew its last bottle and died with a hiss.

What happens to the factory and its things when manufacturing stops? If the process defines the thing, as Kopytoff (1986) contends, then in what kind of process is the abandoned industrial machine involved? What happens to the thing when it is released from the productive phase of its social life? Tim Edensor (2005) observes that industrial order is maintained through networks of objects, humans, spaces, technologies, and forms of knowledge. Without maintenance, those networks fall apart, revealing the impermanence of things and exposing their broken social relations. When disconnected from the processes that made them, formerly industrial objects lose their materiality—that is, the active construction of identity. Edensor argues that the remaining raw material of industrial ruins and abandoned objects ‘rebukes’ the normative assignment of objects and interrogates the nature and history of objects. Though we remain conscious of these past assignments, the ruined or abandoned thing becomes surreal and sensuous. As long as they appear before us, they oblige us to think about machines without people and people without machines.

Phase Three: Heritage, and the Singularisation of the Industrial Thing

For most metallic industrial objects, the ruin phase of existence is a brief interlude lasting only as long as it takes for them to be melted down and fed back into the industrial chain of production. Post-industrial societies, however, have an interesting tendency to lift objects out of that terminal stage and grant them a new existence as heritage. Industrial heritage sites are widespread across America, Europe, and increasingly Asia, and glass museums can be found by the dozen in places like Murano in Italy, Corning (in New York), and Toledo (Ohio), where actual glassmaking has been scaled down or discontinued. Baoshan has joined their ranks thanks largely to Zhang Lin.

Zhang spent much of his early career as a business traveller helping to facilitate the offshoring of American and European glass production and, incidentally, touring many overseas glass museums. Recognising that Shanghai was subject to the same forces of globalisation that were driving industrial glass manufacturing away from its cradle in the West, he began to prepare for the end of glass manufacturing in his city. Partnering with Zhuang Xiaowei at the Department of Fine Art of Shanghai University, Coordination Asia, and logon Architecture, Zhang began the work of transforming Shanghai No. 1 Glass Instruments Factory into the Shanghai Museum of Glass.

The museum is one of only a few such institutions in China that does not receive state funding. Consequently, as at Jianchuan Museum in Sichuan (Ho and Li 2016), developers had a relatively free hand in deciding how it is organised. In the beginning, the Shanghai team leaned heavily on the example and guidance of the Corning Museum of Glass, but ShMoG was intent on forging its own identity. Sometimes referring to itself as a ‘G-park’ (glass park), owing to its sprawling 24-hectare premises, the museum has not taken the path of other post-industrial conversions where original industries have been cleared out to make room for tech hubs (like the 1865 Creative Park in Nanjing), sporting facilities (Shougang Arena in Beijing), and, as Wu Hung (2012) points out, artists’ colonies (798 Art Zone in Beijing). Glass production, though not on an industrial scale, still defines the museum’s mandate and, like glass museums elsewhere in the world, ShMoG tries to preserve its industrial roots. However, it was never meant to be an ‘industrial museum’. According to Tilman Thürmer, the Coordination Asia architect who plotted its development, the museum should constantly evolve, intermingling past and present people and objects as they move through the space (Coordination Asia 2019).

In the museum’s most recent configuration, visitors enter through a musical kaleidoscope and continue through an installation by Tobias Gremmler, who is best known for and perhaps best understood through his video collaboration with Björk on Loss and Tabula Rasa. At ShMoG, Gremmler’s Fusion draws together material (glass), elements (heat, fire, and light), and time. The past is witnessed as residual heat rising through glass conduits from the factory’s original kiln, but in Fusion time does not proceed in a linear fashion; it is arranged in layers and merged with movement, sound, and light. The museum itself does not direct the visitor along any predetermined pathway but encourages them to wander through galleries devoted variously to ‘shapes’, ‘colours’, and ‘dreams’, to negotiate the glass maze, visit the crystal-filled Rainbow Chapel, and tour the childproofed Kids’ Museum of Glass. Artists-in-residence work in design studios, there is a public library, a theatre, a DIY workshop, and part of the former glass factory has been restored. Beyond the galleries, the park succumbs to the need to generate revenue. Visitors are urged to hold their wedding in the Rainbow Chapel, and they are never far from restaurants, coffee, and shops (Glassy Living Store, Arts and Crafts Market). Although the purpose of these concessions is obviously to make money, they are layered into the museum, serving as an implicit reminder that post-industrial societies value consumption over production.

One of the central objectives defined for the museum is to consider the relationship between people and materials. In the perspective of the museum’s chief, the purpose is to move the common understanding of glass from ‘rational’ (理性) to ‘sensual’ (感性) (The Paper 2020). Generally, the museum’s exhibits and installations engage the idea that there is some tension between the immateriality of modern art and glass, which is materials-based, craft-oriented, and cannot be fully extricated from industrial processes. Glass can be idealised and pulled into the sphere of art by releasing it from practical functions like filtering light or retaining fluids, but when used as a medium, glass inevitably pulls art back towards the material base (Yang 2017).

The tension between materials and expression is explored in depth through the museum’s ‘Annealing’ project. Annealing is the final step in the production of high-quality glass, where it is placed in an oven that cools gradually, reducing stress in the glass by allowing the atomic structure to freely arrange itself before transitioning into a stronger object. To develop the project, ShMoG made a point of inviting artists who had not previously worked in glass, expecting that inexperience would cause them to be in dialogue with the glass and to finally reconcile with rather than control the material.

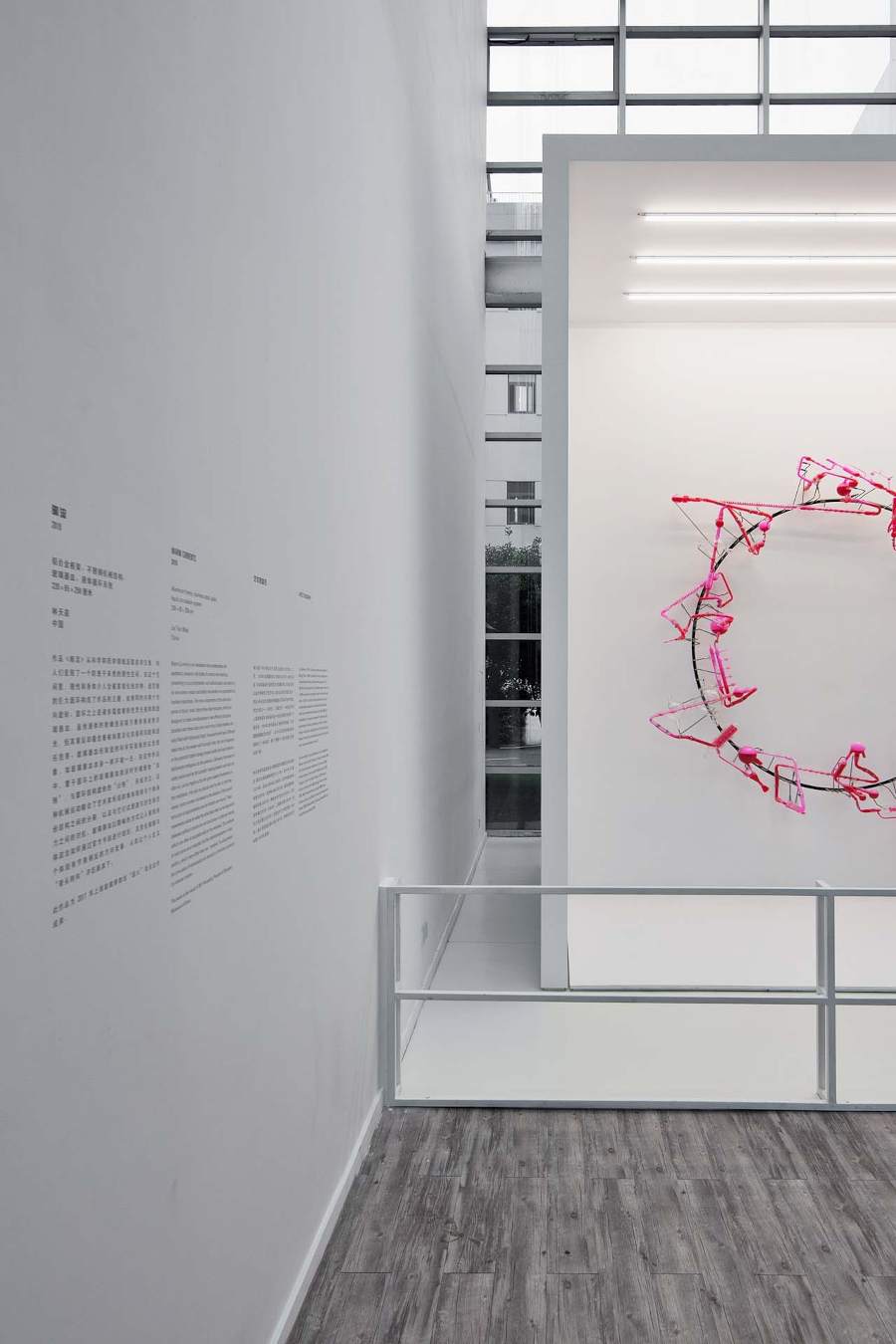

Through the projects, some artists were also in dialogue with the industrial past. In the 2017 installation Thus I Have Heard (如是我闻), Zheng Wenqing applied needles of glass to the surfaces of disused industrial machinery. In Black Substance (黑色物质), Zhang Ding precariously balanced steel plates on black glass spheres on top of other plates balanced on other spheres. In Plain (平坦), Liao Fei attempted (unsuccessfully) to melt the window glass from an old industrial site into new panes, reinsert the panes in the old steel frames, reinstall the windows, and observe the effect on light in the space. One of the museum’s proudest acquisitions, Lin Tianmiao’s Warm Currents (暖流), circulates fluorescent pink liquid through a circuit of tubes and labware reminiscent of the former manufactures of Shanghai No. 1 Glass Instruments Factory (see Figure 4) (Yang 2017).

While the concept of annealing suggests movement towards strength and resilience, many of the exhibits and installations reflect on uncertainty and fragility. The winged Angel in Waiting (天使在等待) by Shelly Xue was part of the museum’s permanent collection until it was damaged by out-of-control children. It remains in place alongside security camera footage of the incident, but under a new title: Broken (折) (see Figure 5). A more intentional engagement with breakage was explored through the BRKN installation/exhibit curated by Tilman Thürmer in 2018–20. Liu Jianhua’s Black Body (黑色形体) required visitors to wear protective shoes and sign a waiver before wading through 14 tonnes of broken glass (Yang 2019: 12). An installation titled The Return (塞归) by Sun Xun employed a device that repeatedly fired a ball bearing against a glass bowl, which, being progressively weakened by the force, must eventually shatter. Sun also experimented with the uncanny and uncomfortable quality of glass through Frontier (塞上), which was named for Wang Wei’s iconic Tang Dynasty poem in which a traveller’s cart drifts along with tumbleweeds and wild geese towards the ‘barbarian sky’ (胡天). The artist explains how glass prompts feelings of ‘alienation, helplessness, the lack of a sense of belonging, or something like a fishbone getting stuck in the throat’ (Shen 2019: 20). The search for its meaning, Sun observes, is like the search for the value of pi—never-ending. Solid and liquid, visible and invisible, glass suggests ‘emptiness in non-emptiness and being in non-being’.

So where does the Owens-Illinois IS glass-forming machine fit in all this? The machine was brought from the old ACI Shanghai factory in 2015 and holds a prominent place in the ‘history of glass’ section of the museum. Most of the display cases in that part of the museum hold quaint and fragile handmade and mouth-blown glassware and ornaments formed by pre-industrial international and Chinese artisans. The double-gob IS glass-forming machine punctures the elegant aesthetics and forces the visitor to turn their attention from art and beauty to industrial brutalism and abandonment. The machine is not shiny glass but dull steel, not smooth but angular, not fragile but resilient, not clear but opaque. It is everything that glass is not, yet it is the thing that made glass. It is modern but obsolete, present but absent, American but somehow Chinese. Its appearance in the museum embodies all the contradictions created when Mike Owens invented its ancestor in 1903; all the contradictions created when ACI took this unit out of service more than a century later; and all the contradictions created when ShMoG decided to exhibit the remains.

The point is driven home by a monitor and a looped video that draw attention to the abandoned ACI factory and its workers. One by one, they stand amid the ruins of their former worksite explaining what they once were, giving their lasting impressions of their occupation, and telling the camera what they do now the factory has closed and the glass-forming machine has been shipped off to the ShMoG. When they can, they say, they work for the property developers who took over the land of their former enterprises, but mostly they hang around, ‘drinking beer and playing mahjong’ (see Figure 6). As in the series of dystopic films analysed by Jie Li (2020), the workers have been ejected from their spaces and occupations. Although ACI Shanghai did not possess a ‘utopian’ connection to Mao-era socialism, memories of belonging to a reform-era community are no less strongly held. The exhibit does not—as it might—portray the machine as dutifully spitting out bottles but places the object in the ruins of its abandoned factory and in the memory of its abandoned operators (see Figures 7, 8, 9). It remembers glass production as it might once have been, but it embraces absence as it is now. It resists the common desire to reinsert things (including human things) back into their relationship with humans. But neither does it re-consign the thing to ruin. The machine’s placement in the museum is key to understanding how curators operate differently to film directors. ShMoG does not try to explain the science or economics of glass or otherwise tell a certain story of the machine or its operators by isolating a certain phase of existence. It allows the display to facilitate slippage or exchange between one phase and another. Yesteryear’s machine is yesterday’s junk and today’s found art object. And they are all at once.

PC: James Flath.

Machines, Museums, and Multiplicities

The developmental history outlined at the beginning of this essay follows glass-forming machines along a quintessentially modern trajectory as they crush centuries-old traditions, spread across the globe, and transform everything down to the way we eat and drink. However, through close attention to the thing, its phases of existence, the materials of which it is made, and the materials it produces, modernity is problematised as a concept. Tina Mai Chen (2012) writes about the ‘human–machine continuum’ in which the Mao-era ‘iron man’ was portrayed as being essentially fused to his equipment. In practice, however, the machine effectively separates the human element from commodity production. In factory production, humans are not elevated by the machine; they are subordinated to it. Where earlier glassmakers were highly skilled and literally breathed their bottles and jars into existence, the Owens machine created a strict division between human work and machine work in the production process, eliminated many of the required skills, and lowered the value of human labour. By interpreting the factory as a process, and the glassmaking machine as a step in that process, we begin to circumvent the artificial dichotomy, or ‘purification’ of difference, between inanimate objects and human subjects—a dichotomy that Bruno Latour (1993) perceives as a basic and problematic condition of modernity. To see or think about the double-gob forming machine in action is to realise what Latour means when he says that such distinctions are artificial, and to understand that the glass factory has never been modern.

When they are transferred to the post-industrial museum, these same machines grind to a halt but take on more layers of meaning. Arjun Appadurai (1986) accounts for this ‘commodity pathway diversion’ by citing Andy Warhol, who decontextualised Campbell’s Soup cans and so was able to interpret them as art. ShMoG partially decontextualises the glass-forming machine, but unlike Warhol’s paintings, the museum retains the actual thing, which stubbornly clings to its productive phase of existence, the unproductive phase of its abandonment, and its materials. These qualities are not artificially arranged into a narrative of modernity but engage the multiplicity of history and memory in a post-industrial society (Barndt 2010). ShMoG operates under the same principle. It endeavours to be (or perhaps is) unstuck in time, but also unstuck in material, light, heat, and motion. By negotiating the contradictions of its existence and relinquishing control over its materials, its space, and ultimately its identity, the museum becomes the annealing oven through which its community must pass on its way to become something stronger—that is, if it does not first break.

References